Forklifts are essential tools in warehouses, distribution centers, and industrial facilities, but they also pose serious safety risks when not operated correctly. Whether you’re a seasoned operator or just starting out, avoiding common safety pitfalls is critical to maintaining a safe and productive workplace.

Here are 10 forklift safety mistakes we see and how to avoid them:

1. Skipping the Pre-Shift Inspection

The Mistake: Rushing into a shift without checking the forklift’s condition.

The Fix: Use a daily checklist to inspect tires, brakes, fluid levels, lights, forks, and alarms. This simple routine prevents breakdowns and accidents.

2. Neglecting to Wear a Seatbelt

The Mistake: Thinking you don’t need a seatbelt because you’re not moving fast.

The Fix: Always wear your seatbelt. In the event of a tip-over, it can be the difference between life and death.

3. Improper Load Handling

The Mistake: Lifting loads that are uneven, unsecured, or beyond the forklift’s capacity.

The Fix: Know the forklift’s rated capacity and center of gravity. Keep loads balanced and secure before lifting.

4. Speeding or Taking Turns Too Fast

The Mistake: Driving too quickly or making sharp turns that risk tipping the forklift.

The Fix: Maintain safe speeds and take turns slowly, especially when carrying heavy or elevated loads.

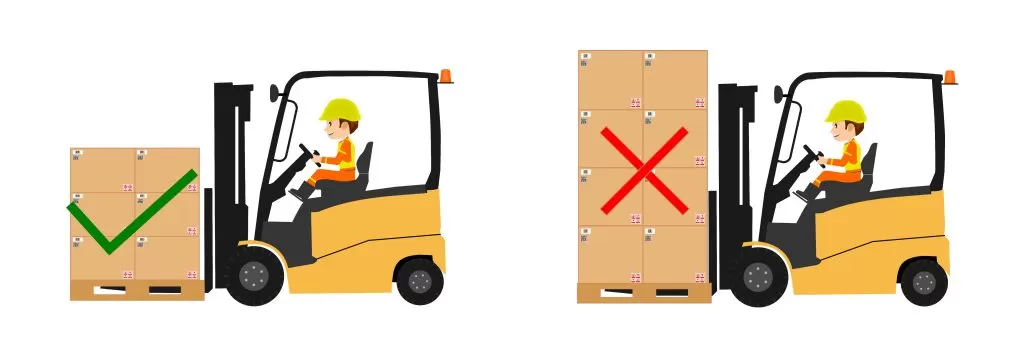

4. Carrying Loads That Obstruct Visibility

The Mistake: Driving forward with tall or wide loads that block your view.

The Fix: If visibility is obstructed, drive in reverse or get a spotter. Always ensure you can see where you’re going.

5. Improper Load Handling

The Mistake: Lifting loads that are uneven, unsecured, or beyond the forklift’s capacity.

The Fix: Know the forklift’s rated capacity and center of gravity. Keep loads balanced and secure before lifting.

6. Operating Without Training

The Mistake: Letting untrained or uncertified personnel operate forklifts.

The Fix: OSHA requires that only trained and evaluated operators use forklifts. Ensure everyone is up to date on training and certifications.

7. Poor Communication with Pedestrians

The Mistake: Failing to alert or make eye contact with nearby workers.

The Fix: Use your horn at intersections, wear hi-vis gear, and establish eye contact with pedestrians before proceeding.

8. Not Lowering the Forks When Parked

The Mistake: Leaving forks raised when the forklift is unattended.

The Fix: Always lower the forks to the floor, set the brake, and turn off the engine before walking away.

9. Ignoring Floor Conditions

The Mistake: Driving over spills, debris, or uneven surfaces.

The Fix: Be aware of your environment. Avoid hazards and report issues to maintenance immediately.

10. Becoming Complacent

The Mistake: Overconfidence or bad habits creeping in over time.

The Fix: Stay sharp. Follow safety protocols every time—no shortcuts, even if you’ve done it a hundred times before.

Forklift safety isn’t just about compliance—it’s about protecting people, equipment, and productivity. By staying aware of these common mistakes and addressing them proactively, you contribute to a safer, more efficient work environment.

Looking to reinforce forklift safety at your facility? Contact us about our OSHA-compliant forklift training programs and operator recertifications.